As producers we organize our barns for lambing according to what works best in our own situation. Here, three producers, from Iowa, Kentucky and Maine, share how they manage their sheep during lambing, with a focus on barn lambing. Producers were asked to describe how their lambing barn is organized and how they manage the flow of ewes and lambs. They also describe the barn’s physical structure, lambing and mixing areas, jugs, feeding, recordkeeping and any special considerations, like the use of barn cameras, creep feeding, etc.

John Bare, DVM, Thistlegrove Farm

Location: central Iowa

Approximate number of ewes/acreage: 70 ewes, 30 acres

Lambing month: March

Our ewes are kept on pasture until the snow gets too deep, then yarded and fed round bales of hay. One week before lambing they are moved into a three-sided 64’x 40′ pole shed. The floor is packed limestone fines with cornstalk bedding. One of the long sides is totally enclosed and faces West. The North and South ends are enclosed but each has 20-foot sliding doors. The East side is open with a 4′ overhang and faces a grove of large trees. When the doors on the North and South side are open, fully 50% of the building sides are open and the ventilation is great. Even closed, there’s good ventilation which is more important than warmth. One thing I can recommend is putting some form of thermal break in your roof; either spray foam it or buy lined steel to  prevent condensation dripping down.

prevent condensation dripping down.

I limit feed hay and grain in hex feeders twice per day. Hay and grain are weighed out to only feed the proper total amount per ewe. After lambing, I feed free choice hay and about a half to a pound of grain per ewe twice daily.

The barn is split in half by a row of eight 5’x 5′ wire panel lambing pens. I leave the pens open to the drop pen and usually ewes try to isolate themselves and drop in the pens. Most days I only go out to the barn morning and night. I gather up recently lambed families and put them in pens so they are out of the way, then feed the rest. Once the lambs are relatively dry, I tag, record, and open up the other side so they can wander out with the lambed ewes. I may give them a half flake  of hay and a drink, but often nothing since most are only penned for a few minutes to a few hours. Ewes and lambs that have issues are left penned with hay and water. If issues persist for more than a day or two, I sell the lambs and the ewe goes to the cull pen.

of hay and a drink, but often nothing since most are only penned for a few minutes to a few hours. Ewes and lambs that have issues are left penned with hay and water. If issues persist for more than a day or two, I sell the lambs and the ewe goes to the cull pen.

Running pregnant ewes with lambs that are even a week old is trouble. The lambs will learn how to snitch from the udders of ewes that have not lambed yet, stealing colostrum. The problem is very bad when limit feeding, as the ewe must choose between eating or fighting off lambs, but I have even had it happen when lambing on pasture. Keeping them separate is the best if you can manage it.

Once lambing is over, I take down the pens and let them have the full barn. I use a creep feeder, but I do not set it up until after lambing is finished. I usually just grind ewe feed for the creep, though I do add Deccox for coccidiosis control.

I have not kept a bottle lamb in years. I run an ad prior to lambing and put together a bottle lamb waiting list. If I have one, I make sure it gets colostrum and then start calling folks on the list and try to get it moved ASAP.

I love my barn cameras. Originally, I got them to sort out mis-mothering, but they have also replaced barn checks. With a barn cam I realized I was visiting the barn way too much; good ewes and lambs figure it out and the ones that don’t need to be culled. I broadcast Wi-Fi towards the barn from the house with a directional range extender. I use a couple pan, tilt, zoom (PTZ) outdoor IP cameras along the open side of the barn with external receiver antennas. PTZ lets you look around, which is great. Cameras have internal memory cards so I can check the recording if I suspect a mis-mothering issue. Once I was out at a school event with my wife, checked the feed on my phone and saw a ewe lamb having a dystocia. I called home and walked my 10-year-old daughter through pulling the lamb while watching the camera feed. I thought it was incredible, but the babysitter… not so much. Sometimes I throw the cameras up on the TV, sit back by the fire and watch them pop. Hard to put a price on what that is worth.

If a ewe or lamb has much trouble or if I lay my hands on a ewe as a veterinarian it means an eventual trip to the sale barn for her and her lambs. I manage what I can to prevent issues, but if problems happen, culling hard is the best option. Commercial flocks can be a bit more forgiving on individual performance, but purebred flocks should be utterly ruthless when culling. You perpetuate what you tolerate.

Leanne Reed, Reed’s Family Farm

Location: east central Kentucky

Number of ewes/acreage: 48 ewes on 15 acres (and up to 40 acres on another farm)

Lambing months: January/February

We bring the sheep from the larger farm to the smaller farm during the last month before lambing. They spend the first few weeks being able to use one large pasture. About one week before the first ewes are due to lamb, they are closed down to a small pasture area close to the house and barn. We bring our ewes into a barn or barn/lot area every night even when not lambing to protect from predators.

We set up eight 8’x 8′ pens and two 6’x 8′ pens in the barn hall. About five days before the first ewe is expected to lamb, we place the ewes who are marked to lamb first in the pens. We generally leave two open pens for ewes who still happen to lamb with the big group. This year we used all 10 pens we had set up but we have gates to be able to make more pens or use the sweep tub if necessary. We use our working system to run the ewes through and separate out those who are expected to lamb first with an emphasis on making sure maiden ewes are in the pens.

We set up eight 8’x 8′ pens and two 6’x 8′ pens in the barn hall. About five days before the first ewe is expected to lamb, we place the ewes who are marked to lamb first in the pens. We generally leave two open pens for ewes who still happen to lamb with the big group. This year we used all 10 pens we had set up but we have gates to be able to make more pens or use the sweep tub if necessary. We use our working system to run the ewes through and separate out those who are expected to lamb first with an emphasis on making sure maiden ewes are in the pens.

We have feeders set up in the barn that are similar to fence line feeders with hay managers above these. Once in the pens/jugs the ewes have their own hay and grain/mineral feeders. Those not in the pens/jugs have access to the small pasture outside the barn during the day and go out to eat hay as well. There is roll baled hay outside and square bales are fed at night in the mangers.

Our barn is sectioned off into 3 areas.  The first area houses the majority of the ewes at night. The middle section holds the pens/jugs and houses up to 10-12 ewes waiting to lamb or have lambed. The third area houses the working system which makes it really convenient to separate ewes into pens. Water is located at the front of the barn. A hose that will stretch to all the pens is used to help water the sheep. Our square baled hay is also located in the front 3rd section of the barn. This makes accessing it very easy even when very cold. Bags with the measured amount of grain for the ewes are hung on posts near the pens.

The first area houses the majority of the ewes at night. The middle section holds the pens/jugs and houses up to 10-12 ewes waiting to lamb or have lambed. The third area houses the working system which makes it really convenient to separate ewes into pens. Water is located at the front of the barn. A hose that will stretch to all the pens is used to help water the sheep. Our square baled hay is also located in the front 3rd section of the barn. This makes accessing it very easy even when very cold. Bags with the measured amount of grain for the ewes are hung on posts near the pens.

We have a creep feeding area that we plan to expand this year. We use a portion of the middle section of the barn for creep feeding with a large creep feeder setup in it.

Our barn is 52’x 60′ with a gravel floor. We wish the barn was larger so we could set up additional pens. Overall, it works really well though. We try to have ewes in the jugs for lambing and then they typically stay for at least 24 hours or longer depending on how they are doing and how soon we need to make room for additional ewes and lambs. Our jugs are made out of small sheep gates and panels. They are 8’x 8′ and 6’x 8′. We try to make sure triplets are in an 8’x 8′ pen. They typically stay up longer so the ewe can be fed specifically for triplets. All 10 of our current pens/jugs have their own hay and grain/mineral feeders in them.

I have a binder that I use to record date, ewe, lambs, description of lambs, tag numbers, and birth weights. We do not use cameras but we have discussed doing this.

When we built our new barn, we built it for the sheep and to use during lambing. We tried to think through its setup so that the handling process would go smoother. All our ewes are inside at night close to lambing so we can easily check on them.

Tom Hodgman, Waldoview Farm

Location: midcoastal Maine

Approximate number of ewes/acreage: 70 Ewes, 80 Acres grazed

Lambing Months: February/March

During late gestation, our ewes are housed inside a three-sided barn with rollup curtain offering shelter from the elements. Ewes lamb inside the same barn. From the time they come off pasture in Nov/Dec, the ewe flock is fed free choice hay in collapsable round bale feeders indoors. Their orts are spread as bedding every few days. When we provide a supplement, such as whole grains or pellets, we use several single-sided Premier-style feeders with an alley between to facilitate distributing feed. Once the ewes have lambed out, we stop using the round bale feeders and load the Premier feeders with hay twice per day from round bales by pitchfork. It’s a little more work but safer for lambs and allows us to control/monitor consumption more closely.

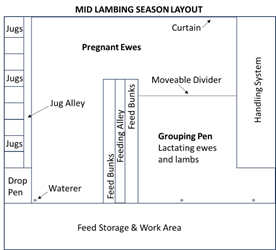

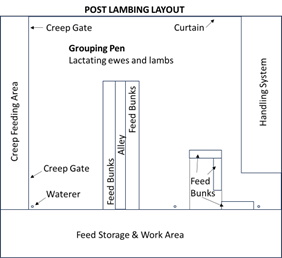

The sheep space is 48’x 60′.  The Premier-style feeders (single sided) are arranged in two rows separated by a 2.5-ft wide alley (walkway) to facilitate feeding. This creates two large open areas on left and right of the feeders, but there’s ample room for sheep to pass back and forth at will. There are no permanent walls inside the barn. We add additional feeders on the right portion to provide additional bunk space especially when lambs are older. We arrange a 6’x 8′ “drop pen” and a row of jugs along an outside wall with an alley in front to facilitate monitoring and moving ewes and lambs. Ewes are placed in the drop pen if they are starting labor. If a ewe lambs in the general population, she and lambs are often moved directly to a jug. Once out of jugs we use a small grouping pen to acquaint three or so litters and their dams before moving to general population of lambs and their dams. The panel divider between pregnant ewes and lactating ewes and lambs is moved frequently to accommodate more ewes with litters over time and fewer pregnant ewes. Consequently, the pregnant ewe pen gets smaller and smaller. Regardless of litter size, all lambs and their dams are housed in the same pen. To maintain the largest possible contemporary group size for NSIP, we do not subdivide by birth type. When there are only 2 pregnant ewes remaining, we move them to the drop pen and the

The Premier-style feeders (single sided) are arranged in two rows separated by a 2.5-ft wide alley (walkway) to facilitate feeding. This creates two large open areas on left and right of the feeders, but there’s ample room for sheep to pass back and forth at will. There are no permanent walls inside the barn. We add additional feeders on the right portion to provide additional bunk space especially when lambs are older. We arrange a 6’x 8′ “drop pen” and a row of jugs along an outside wall with an alley in front to facilitate monitoring and moving ewes and lambs. Ewes are placed in the drop pen if they are starting labor. If a ewe lambs in the general population, she and lambs are often moved directly to a jug. Once out of jugs we use a small grouping pen to acquaint three or so litters and their dams before moving to general population of lambs and their dams. The panel divider between pregnant ewes and lactating ewes and lambs is moved frequently to accommodate more ewes with litters over time and fewer pregnant ewes. Consequently, the pregnant ewe pen gets smaller and smaller. Regardless of litter size, all lambs and their dams are housed in the same pen. To maintain the largest possible contemporary group size for NSIP, we do not subdivide by birth type. When there are only 2 pregnant ewes remaining, we move them to the drop pen and the  entire floor of barn (except for jugs) is accessible to nursing ewes and their lambs.

entire floor of barn (except for jugs) is accessible to nursing ewes and their lambs.

We start offering lambs creep feed when the oldest ones are three weeks old. The jugs furthest from the drop pen are dismantled first so that space can be used for creep feeding. As more and more lambs begin using creep, and fewer and fewer pregnant ewes remain, we continue to disassemble jugs until the entire jug area and drop pen are converted to a single creep feeding area.

We do not maintain a pen for orphan lambs, nor do they come to the house. A hypothermic lamb is moved to a heated space adjacent to the barn and returned to its dam ASAP. Orphaned lambs, whether fed exclusively or supplemented on a bottle, are housed with the general population. They quickly take to creep feeding and are allowed to develop more naturally alongside other lambs.

The overall barn is 60’x 70′. We maintain tractor access to a 12’x 70′ area for storing feed and hay. The sheep have access to the main area (48’x~60′). Our handling system occupies the remaining space. The floor is concrete with a 20’x 70′ concrete slab outside draining to a manure pit for composting the bedding pack.

We purposely built the barn with no interior walls to facilitate the constant movement of panels to arrange/rearrange pens for any need. I wish the slab on back of barn was 4′ wider to better facilitate safely maneuvering a tractor near the manure pit.

When lambing indoors, we almost always jug our ewes and lambs. They normally remain in jugs for three days. Older ewes or experienced ewes with a single lamb may stay for just 24 hrs before moving to the grouping pen. Ewes or lambs that require monitoring or treatment will stay in a jug (or double jug) for four or five days or rarely longer if needed.

Our jug set up consists of a drop pen with an alley to nine individual jugs. Each of our jugs measures 5’x 4′. Jugs are attached to the barn wall with eye screws and steel rods. Our preferred side panels are lightweight steel panels by Sydell. The fronts are mostly wooden made of 1″x 6″, rough-sawn lumber. Sides and fronts are connected by vertical steel rods. We use a Pipestone-style box attached to jug fronts for feeding hay (We do not feed grain to ewes in jugs). The wooden box is easily attached to the front jug panel with wood screws. We offer water in a small bucket in a front corner of each jug. We are considering the Pipestone-style PVC water pipe if we can keep it from freezing and if it saves labor.

We try not to overcomplicate data collection. The little “Lambing Record Book” available from KHSI is what we use. It lives in my jacket pocket for the duration of lambing season. I modify some of the columns to better suit our needs, such as adding narrow columns for lambing ease, lamb vigor at birth, and for vaccinations. Once each page of the lambing book is completed, I scan it to ensure we don’t lose any data.

We use three Ring cameras to monitor activity in the barn during lambing season. We have two placed to monitor the main areas and one to give an overview of most jugs plus a blind spot for the other cameras. At our location, the cameras require WIFI, so we have a router located in the barn as well.

We designate a narrow alley, just wide enough to walk down comfortably, to facilitate moving ewes and lambs from our drop pen to jugs. It also allows us to offer feed and water to jugs while minimizing interaction with the pregnant ewes and provides a work space outside a jug to tube feed a lamb or to process a lamb (weighing, tagging, etc.). It may seem like wasted space, but we find it well worth it.

Invariably a ewe will deliver without us knowing it. Many times, her lambs can be picked up and brought to a jug with mother following along. Occasionally however, it might be better to leave them where they are especially if the ewe is nervous or a first-timer. In this case, we use a bi-folding panel to quickly turn a corner of the pen into a make-shift jug. We’ve found there are many scenarios when this can be useful. Having three or four of these available, just in case, saves our time and reduces stress on nervous ewes.

We use three Nelson auto-waterers in our lambing barn. They save so much time and are easily cleaned out and kept fresh. Because we live in the north, the heating element under the stainless bowl is key to keep water flowing on the coldest nights. The entire south wall of our barn is covered by a 70-ft long vinyl curtain which rolls up by an electric motor (cordless drill powered curtains are also an option). This allows us to manage air flow/quality in minutes with the flip of a switch.

![]()